Bulk Material Handling Equipments

You’ll discover an extensive array of high-performance bulk material handling equipments by Temekna designed to streamline processes, improve efficiency, and elevate productivity across a diverse range of industries. Our top-quality equipment is engineered to handle various materials with precision and reliability.

What are Bulk Material Handling Equipments?

Bulk material handling equipment refers to machinery used to handle and transport bulk materials in large quantities from one location to another within a facility or from one facility to another. These equipment play a critical role in industries where materials such as powders, grains, ores, aggregates, chemicals, and other bulk commodities need to be efficiently managed and moved.

Uses of Bulk Material Handling Equipment:

- Transportation: Efficiently move bulk materials from one point to another, aiding in processes like loading, unloading, and material transfer within a facility.

- Storage and Stockpiling: Store bulk materials in silos, bins, hoppers, or piles for organized inventory management and subsequent processing.

- Processing and Manufacturing: Integrate into production processes to feed raw materials, mix components, blend materials, and facilitate manufacturing operations.

- Packaging and Distribution: Assist in packaging bulk materials into smaller units for distribution or further processing.

- Loading and Unloading: Load bulk materials onto trucks, ships, railcars, or containers for transportation, and unload them at their destination points.

Types of Bulk Material Handling Equipment:

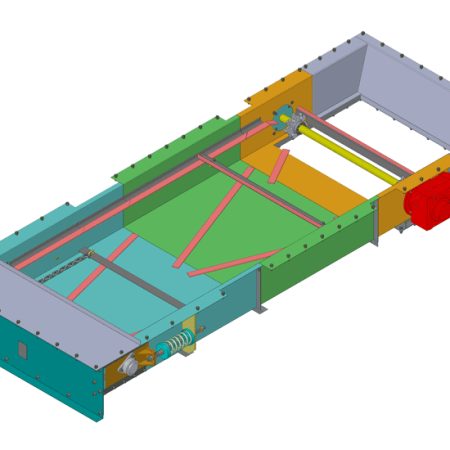

- Conveyors:

- Belt Conveyors: Use continuous belts to convey materials horizontally or at an incline.

- Screw Conveyors: Use a rotating screw blade to move materials horizontally, vertically, or at an angle.

- Bucket Elevators: Utilize buckets attached to a belt or chain to vertically convey materials.

- Hoppers and Silos:

- Hoppers: Provide temporary storage for materials and aid in regulating material flow.

- Silos: Tall, cylindrical structures used for long-term storage of bulk materials, often found in industries like agriculture and mining.

- Feeders:

- Vibratory Feeders: Use vibrations to move and meter materials, ensuring a consistent flow into downstream processes.

- Apron Feeders: Use overlapping pans or plates to feed bulky or heavy materials to crushers or conveyors.

- Stackers and Reclaimers:

- Stackers: Stack bulk materials in a stockpile, facilitating organized storage and efficient material retrieval.

- Reclaimers: Retrieve materials from stockpiles, ensuring a continuous supply to downstream processes.

- Crushers and Screens:

- Crushers: Reduce the size of bulk materials for further processing or transportation.

- Screens: Sort and classify bulk materials based on size and other characteristics.

- Loaders and Unloaders:

- Front-End Loaders: Load bulk materials into trucks, bins, or hoppers.

- Ship Loaders and Unloaders: Load and unload bulk materials onto or from ships.

- Dust Collection Systems:

- Collect and manage dust generated during material handling processes, ensuring a clean and safe working environment.

Each type of bulk material handling equipment serves a specific purpose and is selected based on the material being handled, the volume of material, the distance of transportation, and other operational requirements in various industries such as mining, agriculture, construction, manufacturing, and logistics.

Our Products

Showing all 5 results